In the world of automotive repair, a Ford timing tool manufacturer plays a critical role in ensuring accurate camshaft and crankshaft alignment. Whether you're working on a Ford EcoBoost or a V6 engine, precision is the difference between smooth performance and costly rework.

With modern Ford engines featuring variable valve timing (VVT) and tight tolerances, high-quality timing tools are essential for engine rebuilding, maintenance, and service networks worldwide.

1. Understanding Ford Timing Tools

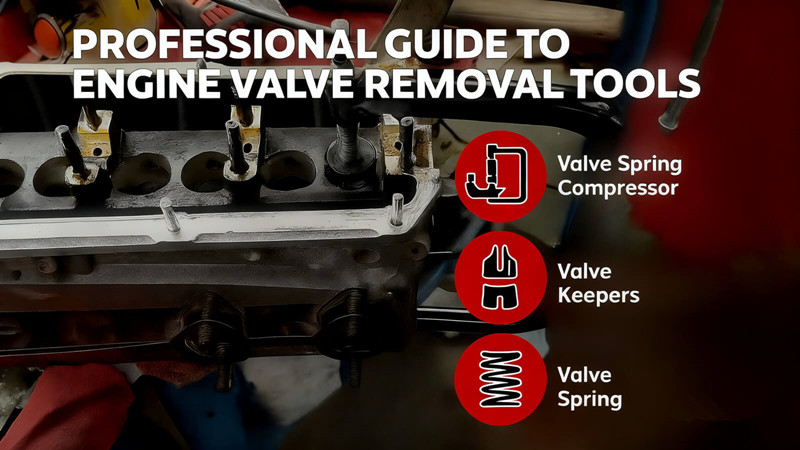

Ford timing tool kits are designed to hold and align engine components during service procedures such as timing chain or belt replacement.

A complete set typically includes:

-

Camshaft alignment plates

Professional mechanics rely on these kits to maintain factory timing accuracy—especially on Ford EcoBoost, Duratec, and V6 Ti-VCT engines.

2. Top Ford Timing Tool Manufacturers (2025 Overview)

When it comes to precision engine maintenance, choosing the right Ford timing tool manufacturer is critical. Whether you are servicing EcoBoost, Duratec, or modular V6/V8 engines, the following global manufacturers are recognized for delivering dependable, high-tolerance timing kits designed specifically for Ford vehicles.

1. FUERD

Strengths:

-

Vertically integrated: casting, CNC machining, stamping, and injection moulding – all in-house. This ensures consistency, cost control, and full traceability.

-

OEM/ODM capabilities for private-label or customized timing tool kits.

-

Supplies timing tools for global brands such as Ford, BMW, Volvo, Fiat, Renault, and Land Rover.

-

Certified with ISO9001, IATF16949, CE, and other international quality systems.

Weaknesses / Considerations:

-

For highly specialized or ultra-premium engine series, additional validation or finishing may still be required.

-

Shipping time and import duties may vary depending on the region.

Ideal For:

-

Cost-conscious professionals and workshops handling multiple vehicle brands.

-

Distributors looking for private-label or fully customized tool solutions.

-

Buyers seeking strong quality-to-cost balance and reliable delivery performance.

2. CTA TOOLS

Strengths:

-

Recognized U.S.-based specialty tool brand with a well-established “Timing Tools” line.

-

Offers timing kits for Ford, GM, and other American engines (e.g., Ecotec 1.4L, Ford EcoBoost series).

-

Strong logistics, warranty, and customer support across North America.

-

Covers various timing-related tools including locking pins, camshaft/crankshaft alignment tools, and tensioner adjustment kits.

Weaknesses / Considerations:

-

Limited global distribution; higher costs and longer lead times for non-U.S. buyers.

-

Update cycle for newer or European engines can lag slightly behind OEM tool releases.

Ideal For:

-

Workshops focusing on U.S. domestic vehicles or North American markets.

-

Buyers valuing brand familiarity, local service, and quick product access.

-

Technicians wanting mid-to-high-tier tools with reliable U.S. support.

3. OTC TOOLS

Strengths:

-

A legacy American brand (Bosch Automotive Service Solutions) known for professional-grade diagnostic and service tools.

-

Offers OEM-equivalent Ford timing tool kits covering a wide range of engines (Duratec, EcoBoost, Powerstroke).

-

Excellent technical documentation, compatibility charts, and repair manuals for technicians.

-

Robust build quality with consistent engineering precision.

Weaknesses / Considerations:

-

Premium pricing relative to some Asian or independent brands.

-

Product updates may prioritize dealer-level users rather than independent workshops.

Ideal For:

-

Dealerships, authorized service centers, or professional mechanics.

-

Buyers prioritizing OEM-level accuracy, documentation, and long-term reliability.

-

Users who prefer established U.S. engineering and full after-sales support.

4. LISLE CORPORATION

Strengths:

-

Over 100 years of U.S. manufacturing heritage; well-known for innovative automotive specialty tools.

-

Offers select Ford timing and camshaft holding tools, tensioner locking tools, and valve service kits.

-

Durable, field-tested designs often used in professional garages across North America.

-

Simple, effective, and affordable solutions designed for reliability and ease of use.

Weaknesses / Considerations:

-

Product line may not cover every modern or non-U.S. engine.

-

Lacks extensive OEM certification compared to larger industrial brands.

Ideal For:

-

Independent workshops, maintenance garages, and DIY professionals.

-

Buyers valuing straightforward, proven tool designs from a reputable U.S. manufacturer.

-

Technicians seeking durable and cost-effective solutions for common timing repairs.

5. OMT (Orion Motor Tech)

Strengths:

-

U.S.-based brand offering competitively priced timing and engine service tools with wide online availability.

-

Covers Ford, BMW, VW, and other mainstream engines with accessible kits.

-

Known for affordability and versatility—ideal for general-purpose repair work.

-

Tools are typically supplied with comprehensive storage cases and usage guides.

Weaknesses / Considerations:

-

Not an OEM supplier; precision and finish may vary by kit.

-

More suited to moderate or general-use applications than professional, heavy-duty operations.

Ideal For:

-

Budget-conscious buyers and small workshops.

-

Hobbyists, DIY users, or those seeking functional, easy-to-order timing tool kits.

-

Retail and e-commerce distributors prioritizing accessible price points and broad appeal.

3. What Makes a Reliable Ford Timing Tool Manufacturer

A professional Ford timing tool manufacturer must meet strict engineering and material standards. Below are the key criteria that separate top-tier suppliers from generic ones:

|

Factor |

Why It Matters |

|

Material Quality |

Tools made from Cr-V or H13 steel withstand repeated high-torque operations. |

|

Precision & Tolerances |

CNC accuracy within ±0.002 mm ensures consistent cam-crank synchronization. |

|

Engine Compatibility |

Proper kits must match each Ford engine family (EcoBoost, Duratec, Ti-VCT). |

|

Certifications |

Compliance with IATF16949 / ISO9001 guarantees OEM-level production quality. |

|

Support & Documentation |

Illustrated manuals, replacement parts, and warranty service build professional trust. |

4. Recommended Ford Timing Tool Kits by Engine Type

|

Engine Type |

Typical Kit |

Main Components |

Suitable For |

|

1.0L EcoBoost |

7-Piece Kit |

Cam phaser locks, crank TDC pin |

Fiesta, Focus (2012–2023) |

|

2.0L EcoBoost |

9-Piece Kit |

Phaser adjuster, crank lock pin |

Focus ST, Escape, Fusion |

|

3.5L / 3.7L V6 |

12-Piece Kit |

Dual camshaft locks, flywheel holder |

F-150, Explorer, Edge |

These kits are used globally by workshops and distributors who partner with Ford timing tool manufacturers offering OEM or private-label customization.

5. Key Trends Among Ford Timing Tool Manufacturers

a. OEM vs Aftermarket Production

OEM suppliers focus on high tolerance and Ford-specific design validation, while aftermarket manufacturers emphasize affordability and universal fitment.

b. Precision Machining Evolution

CNC machining at micrometer-level accuracy (≤0.002 mm) is now the industry standard, minimizing timing drift and misalignment during engine rebuilds.

c. Sustainability and Quality Compliance

Leading suppliers follow RoHS, CE, and ISO9001 standards to ensure long-term reliability and environmental safety.

d. Custom Branding & Private Label Services

Distributors increasingly seek manufacturers offering OEM/ODM Ford timing kits, allowing them to sell under their own brand with custom packaging.

6. Leading OEM-Grade Example: FUERD Machinery

As a benchmark Ford timing tool manufacturer, FUERD Machinery integrates precision casting, CNC machining, and automated inspection to deliver tools meeting OEM standards.

FUERD’s kits for Ford EcoBoost and V6 engines feature heat-treated Cr-V steel, 0.002 mm tolerances, and 14-month warranties—making them a preferred choice among global distributors and repair specialists.

Final Thoughts – Choosing the Right Ford Timing Tool Manufacturer

The demand for Ford engine timing tools continues to grow as EcoBoost and Ti-VCT engines dominate the market.

When comparing Ford timing tool manufacturers, prioritize precision, certification, and support over price alone.

Suppliers like FUERD, Laser Tools, and OTC represent the best balance of quality, value, and professional trust—ensuring every timing service achieves OEM-level performance.